AEROSPACE MRO WITH 3D PRINTING

Cut costs, logistics, and lead time with 3D printed aerospace MRO for custom and low-volume parts.

You can't wait to find out, how you could use 3D printed MRO parts?

REDUCE LEAD TIME

Minimize logistics and produce aerospace MRO in weeks, not months.

SAVE costs

Cut costs with 3D printed parts for custom and low-volume production.

IMPROVE PERFORMANCE

Improve MRO performance with easy iteration, custom designs, and complex parts.

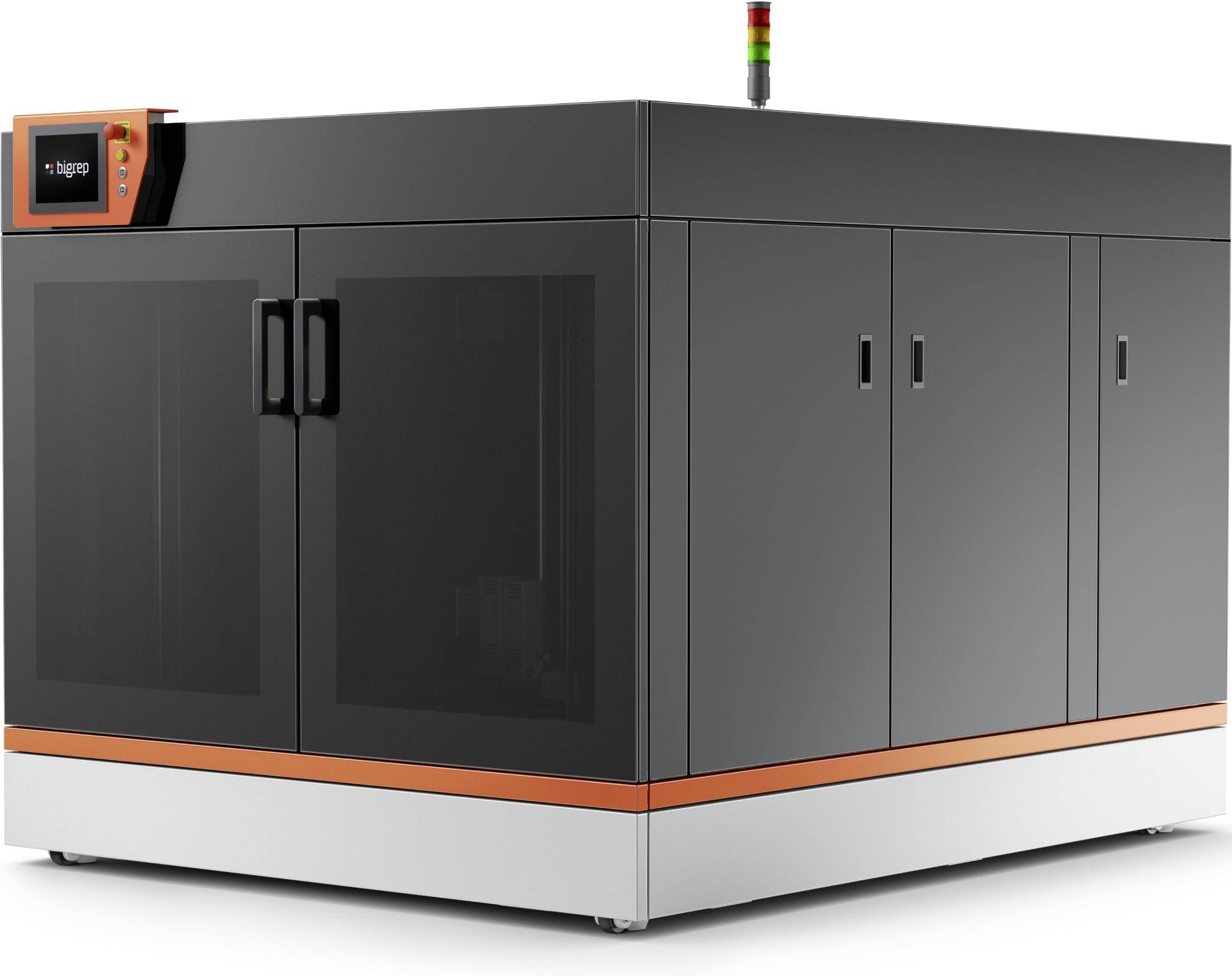

Aviation MRO (Maintenance, Repair, and Overhaul) tools refer to the specialized equipment, software, and resources used to keep aircraft in peak condition, essential for ensuring the safety, reliability, and airworthiness of aircraft. Aerospace MRO tools may need to be customized or produced in low-volume, a perfect task for BigRep large-format 3D printers.

The aerospace industry was drastically effected by the Covid-19 pandemic, with flights halted and planes grounded. As MRO tools are integral to the safe storage of aircraft, several BigRep customers found their 3D printers as essential to produce the parts they needed, while even improving their performance and speeding up production from months to just weeks.

Problems of Traditional MRO Production

Expensive material and labor costs

Slow to iterate and produce

Heavily dependent on supply chain

Outsourced to third party supplier

NDA required for external providers

Solutions with 3D-Printed MRO

Minimal material and labor cost

Agile production easy to iterate and customize

Digitized with no physical inventory

Produced in-house on demand

Design knowledge is protected in-house

Top Performance from 3D-Printed Blade Restraint Cradles

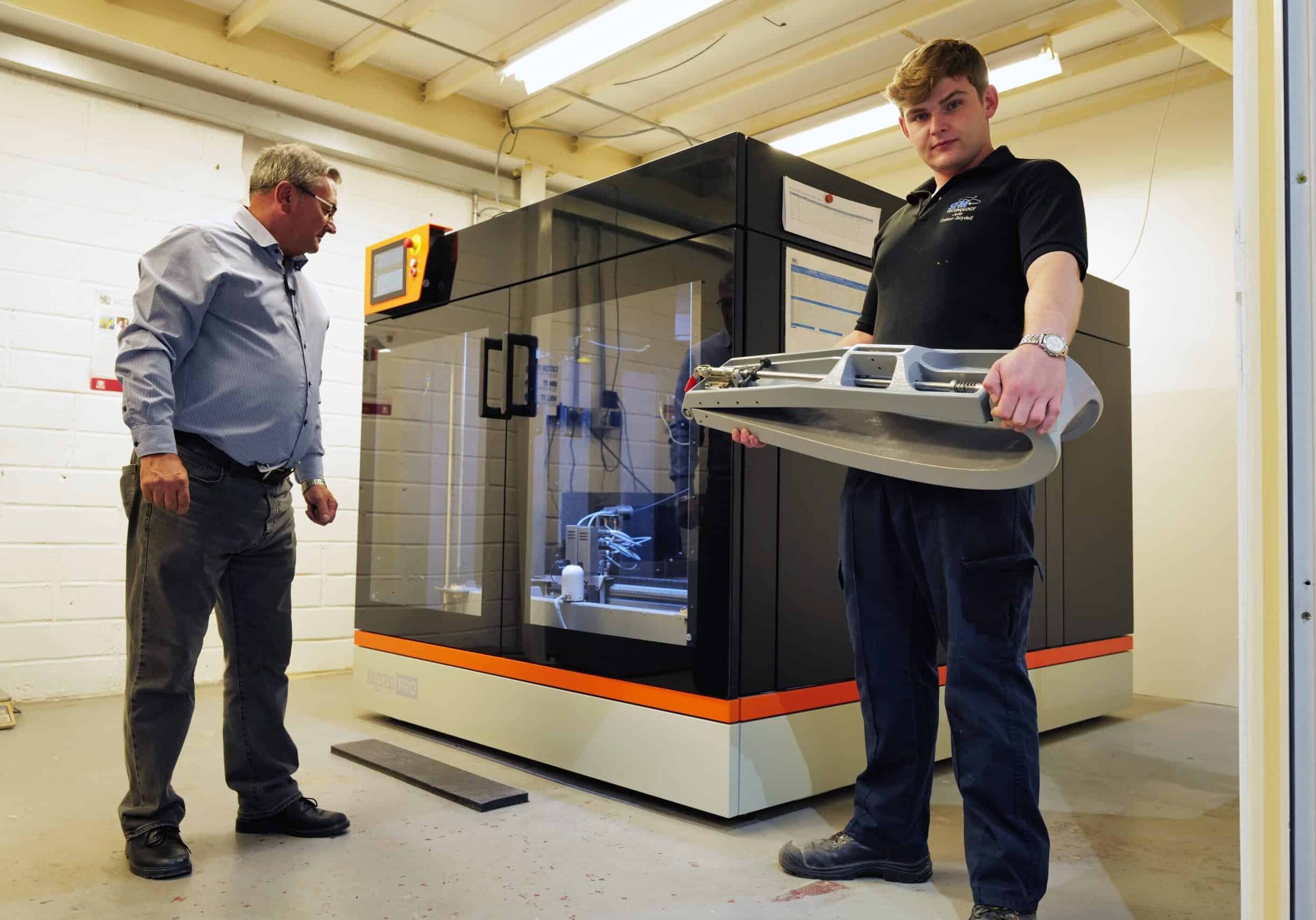

When the UK's Ministry of Defense and Leonardo found that their pre-existing helicoptor blade restraint cradles were not living up to their standard, they turned to SFM Technology to develop the first 3D-printed blade restraint cradles. measuring 900x230x160 mm, the restraints are post-processed to withstand weather and seawater to outperform parts made using traditional methods.

3D-Printed Restraints

SFM uses the BigRep PRO to 3D print the end-use parts with BigRep's HI-TEMP CF filament.

Embedded Hardware

3D printed restraints are fitted with hardware including a clamp to secure the helicopter blades in place.

Post-Processed Surfaces

Finally, the 3D-printed end-use parts are post-processed to withstand weather and seawater.

Accelerated Maintenance with

3D-Printed Aircraft Engine Covers

COVID-19 ignited a domino effect in global supply chains and, specifically, airlines encountered limited ground-service equipment availability. Scandinavian Airlines needed additional engine exhaust covers for their grounded planes, but short supplies and increased demand made this impossible. Therefore, CNE Engineering developed 3D printed molds for low-volume production of urethane engine covers, avoiding blocked supply chains and delivering within weeks.

3D Printed Mold

CNE 3D prints molds using the BigRep ONE and STUDIO with HI-TEMP CF, PLX, and TPU 98A.

Urethane Casting

The 3D-printed mold are combined to cast urethane plugs, which are chemically resistant and UV tolerant.

Low-volume Production

Scandinavian Airlines needed less than 100 engine covers to be produced quickly and inexpensively.

Talk to an Expert

We have a team of experts ready to answer all your questions. Do not hesitate to get in touch to get more information about Additive Manufacturing, best materials for your application, and how to implement it in your business!

You THINK BIG, we'll help you get there!