Concrete Casting with

3D Printed Formwork

Digitize Production to Create Complex Concrete Formwork Faster and Cheaper

You can't wait to find out, how you could make your own 3D printed formwork?

3x FASTER

Produce complex formwork at lightning speed with reduced lead times.

30% CHEAPER

Save money with reduced costs of digital craftsmanship.

COMPLEX FORMS

Achieve complex shapes unthinkable with traditional methods.

Concrete formwork in construction can make up 40 - 60% of a total budget, especially for complex shapes such as curved concrete forms. Some designs like organic shapes, double curved surfaces, and cavities are simply not feasible to produce because they require highly skilled laborers to produce customized formwork resulting in high costs, long lead times, and material waste.

BigRep 3D printers can produce large-scale, complex formwork up to 3x faster at a fraction of the cost of traditional methods. With the new CONCRETE FORMWORK filament developed by BASF Forward AM and BigRep, you can unlock the massive benefits of 3D printed formwork.

Advanced Applications with

3D Printed Formwork

BigRep 3D printers empower customers and partners to produce concrete formwork for building restoration, concrete facade panels, precast concrete stairs, public sculptures, and more.

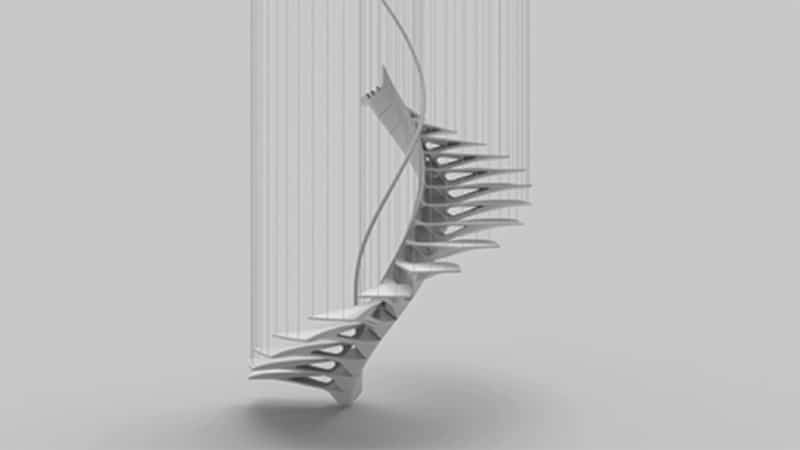

BESPOKE STAIRS, NEST STEP2 UNIT

Designed by DBT at ETH Zurich partnered with BASF Forward AM, ROK, SW Umwelttechnik and WaltGalmarini. NEST by EMPA is an innovative building utilizing digital fabrication and circular economy.

Image © DBT / ETH Zurich

BB Beton, Public Sculpture

BB Beton uses 3D printed formwork to produce large-scale concrete sculptures for public parks in Stockholm.

Image © Veilhan, Alexis Bertrand / Bildkunst and Robin Hayes, 2020

Dreßler Bau, Custom Curtain Wall

This curtain wall is a custom-designed facade panel developed by BASF Forward AM with BigRep technology for Dressler Bau.

How to Produce 3D Printed Formwork for Concrete Casting

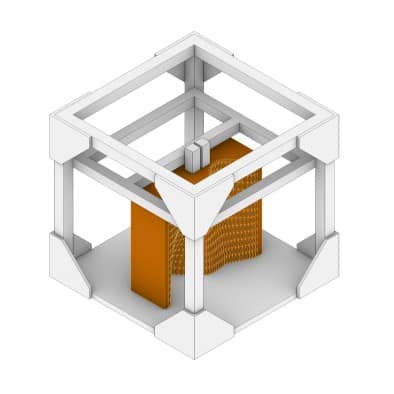

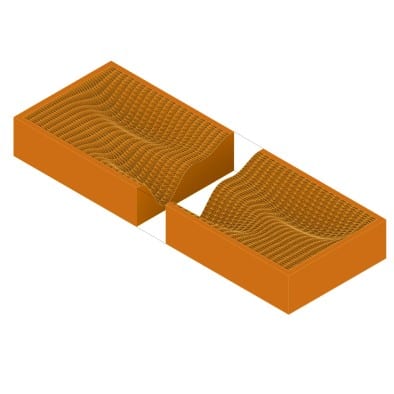

3D printed formwork is a perfect solution for casting complex geometries. The first step is to design and print the formwork. For restoration projects, it is also possible to scan existing elements to create the 3D models for the formwork.

If the formwork is larger than BigRep print volume (1m3 on the BigRep ONE, for example) then it can be printed in parts and assembled after. If needed, the 3D printed formwork can be post-processed with a variety of methods. It is also possible to combine traditional formwork for simple shapes with 3D printed formwork for complex parts. Then the concrete is cast using standard methods. Finally the formwork can be cleaned and reused.

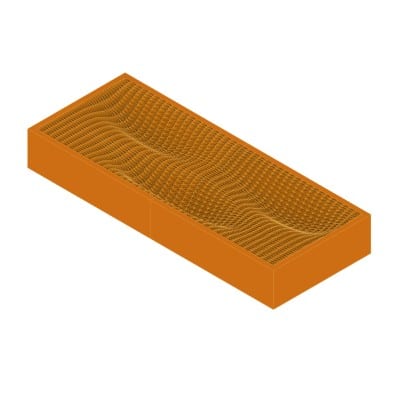

Step 1

3D Print the formwork

Step 2

Assemble the parts

(for extra large formwork)

Step 3

Post-process the formwork

(if needed)

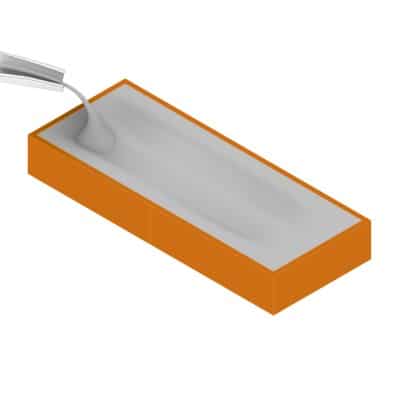

Step 4

Cast concrete using standard methods

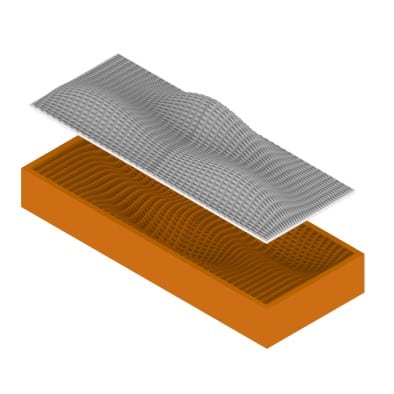

Step 5

Clean and reuse the formwork

Recommended Products

Talk to an Expert

We have a team of experts ready to answer all your questions. Do not hesitate to book a free online call to get more information about Additive Manufacturing, best materials for your application, and how to implement it in your business!

You THINK BIG, we'll help you get there!